Recently, Feedstock-Technology-Product (FTP ) has been stressed for the biofuel sector.

The CSIR-IIP pilot plant in Dehradun produces 30 liters of sustainable air fuel.

What are the benefits of FTP approach?

|

Generation |

Feedstocks |

Example |

|

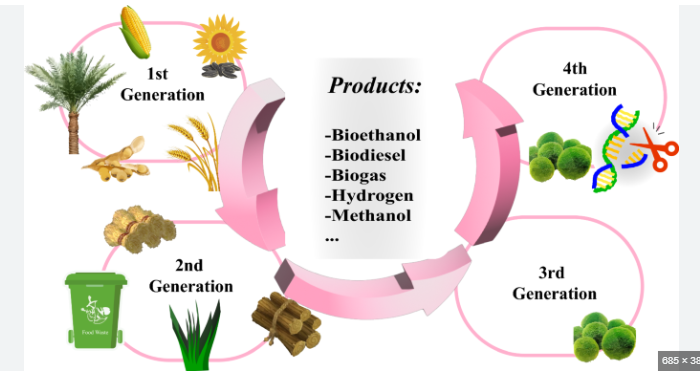

First generation (1G) |

Molasses, sugarcane syrup, and surplus grains. |

Bioethanol, biodiesel, biogas |

|

Second generation (2G) |

|

Cellulose ethanol, biodiesel |

|

Third generation (3G) |

Algae- It consists of 40% of lipids which can be converted to biodiesel or synthetic petroleum. |

Algal Biofuels Butanol, Gasoline, Jet fuel |

|

Fourth generation (4G) |

Genetically engineered bio algae |

Biodiesels and other bio fuels and products. |

|

|

||

What are the opportunities in biofuel production for India?

Total food grain and horticulture production in 2023-24 period were about 320 million tonnes and 350 million tonnes.