7667766266

enquiry@shankarias.in

What is the issue?

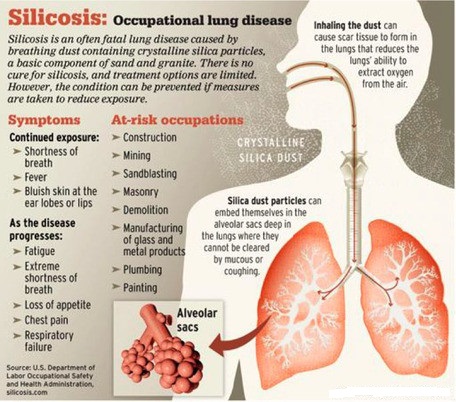

Countless workers engaged in mines, construction and factories in India are silently dying of exposure to dust (Silicosis), utmost exploitation and apathy.

What is silicosis?

What is Rajasthan’s model for Silicosis prevention?

Rajasthan has the top-most share of over 17% in value of mineral production in India.

What are the shortfalls in the system?

Why is reporting the cases significant?

What are the other provisions and concerns in the OSHWC Code?

Section 6 of the Code - Annual health checks free of cost to the employees

Section 20 - Powers to the DGMS to conduct health and occupational surveys in mines

What are the measures needed?

Source: The Hindu