7667766266

enquiry@shankarias.in

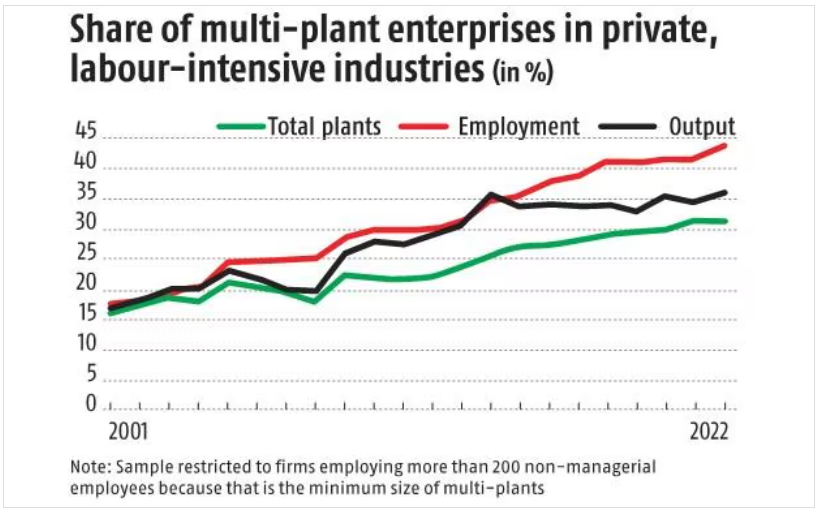

India has been under-performing in labour-intensive manufacturing sector for past two decades.

|

India’s targets in manufacturing sector |

|

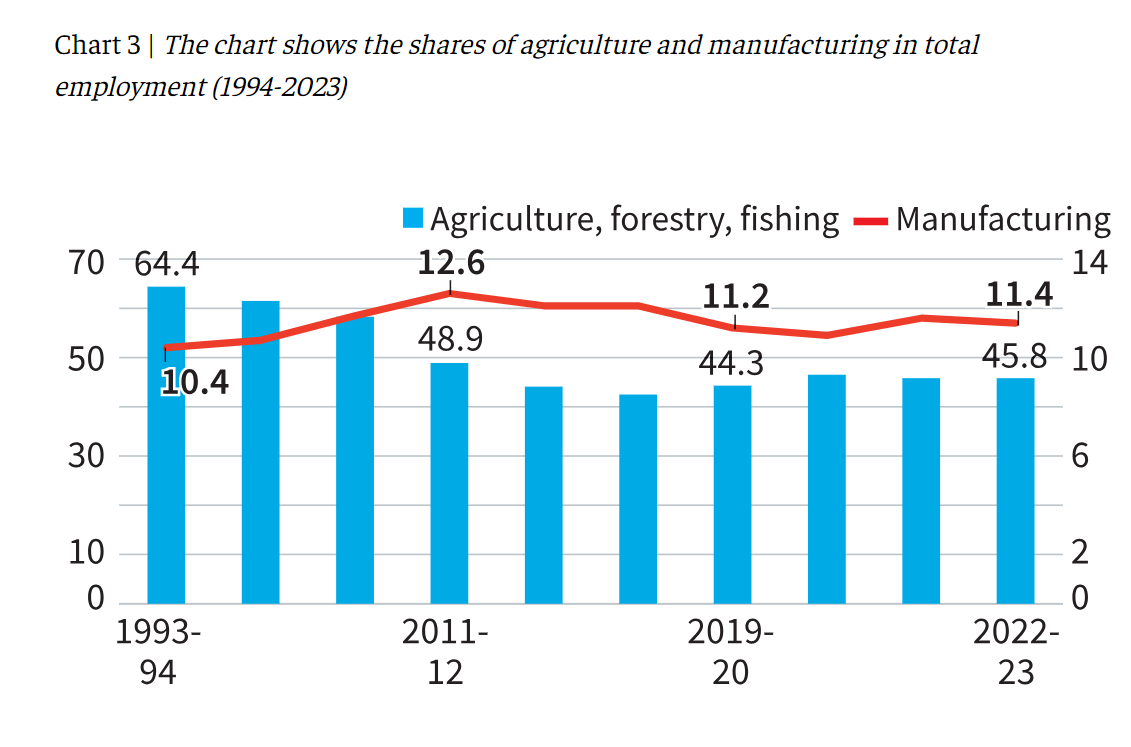

NSSO sample surveys, manufacturing employment has declined from 12.6% in 2011-12 to 11.4% in 2022-23.

The Industrial Disputes Act, 1947 mandates a threshold of 100 employees for establishments to lay off employees or shut down without having to seek government approval.

The Annual Survey of Industries (ASI) is the principal source of industrial statistics in India. The Annual Survey of Industries (ASI) is being conducted since 1959 under ministry of labour and employment.